Applications

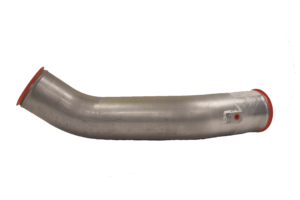

H-P manufactured air intake tubes complete the critical area between filter and engine, our High Performance cleaning and bending programs make a real-world difference.

Air intake applications are typically aluminum and often include welded on mounting or attachment brackets. Strict cleanliness specifications are critical as are leak-proof welds. With space limited in today’s engine compartments, H-P’s ability to make tight compound bends is equally important.

Our High-Performance ability to custom engineer, provide precise prototypes, make short radius bends, weld and deliver clean parts are all important in making air intake tubes. Because of the number of parts supplied for these applications, we also often provide kitted packaging to help customers cut inventory, picking, and assembly costs.

Key High-Performance Capabilities: Engineering, prototyping, welding, kitting, and tube cleaning to exacting standards including SAE J 1726

Key Markets for H-P Air Intake Parts:

- Any type of off or on-road vehicle

- Anything with a diesel engine

- Generators and stationary power sources

- Cranes and aerial lifts

- RVs